Introduction to Container Number Recognition

Container number recognition is revolutionizing the logistics industry. With millions of containers moving globally each year, efficient management and accurate tracking are crucial. Container number recognition systems (CNRS) offer advanced optical character recognition (OCR) capabilities that streamline the identification of container numbers. These systems utilize real-time video processing to capture and recognize container identification numbers, ensuring seamless operations at ports and terminals.

Container Number Recognition Software (CNRS) technology significantly improves efficiency and accuracy in the logistics supply chain. By automating the detection and identification of container numbers, these systems reduce the need for manual intervention. This automation not only saves time but also minimizes human errors, leading to more reliable data and smoother workflows. For instance, the recognition of ISO 6346 container codes ensures compliance with international standards, facilitating the global movement of containers.

One key advantage of container number recognition is its ability to handle various lighting conditions and environmental challenges. Advanced OCR algorithms can recognize container markings even in low-light scenarios, ensuring accurate data capture around the clock. Moreover, the integration of license plate recognition and ANPR systems enhances security by verifying vehicle and cargo information in real-time.

Furthermore, the scalability of Container Recogntiion Software (Container Number Recognition Software (CNRS) solutions allows for easy integration with existing terminal management systems. This flexibility ensures that ports and logistics operators can adopt these technologies without significant disruptions. As a result, container number recognition systems play a vital role in improving efficiency and throughput at busy port terminals or bulk terminals during peak hours.

Supplai, a leader in OCR technology, provides cutting-edge solutions tailored to the specific needs of the logistics industry. Their systems offer unparalleled speed and accuracy, making them essential tools for modern container management. By leveraging Container Number Recognition Software (CNRS), logistics operators can achieve faster and more efficient container processing, ensuring a smoother supply chain and better service for their customers.

Understanding Container Number and Container Code Systems

Container number and container code systems are fundamental to the logistics and shipping industries. A container number is a unique sequence assigned to each container, enabling its identification and tracking throughout its journey. Typically, this number includes a combination of the owner code, serial number, and check digit, adhering to the ISO 6346 international standards.

The owner code, comprising three capital letters, identifies the container’s owner. This prefix is followed by a six-digit serial number, and finally, a single check digit for verification. These elements collectively form the container number, ensuring that each container is uniquely identifiable. Accurate recognition of these numbers is crucial for managing the movement of containers globally.

The ISO 6346 standard, established by the International Standards Organization, governs the structure and marking of shipping container codes. Compliance with this standard ensures consistency and reliability in container identification across different countries and companies. This standardization facilitates international trade by simplifying the logistics of tracking and managing containers.

Container number recognition systems utilize OCR technology to automate the identification of these container codes. These systems employ advanced recognition algorithms to detect and read the container identification number accurately. By processing images captured by IP-cameras, Container Number Recognition Software (CNRS) can identify containers entering and leaving any port terminal, regardless of lighting conditions or other environmental factors.

Moreover, these systems are designed to handle various types of containers, including dry containers, refrigerated containers, and tank containers. This versatility makes them indispensable tools for the logistics industry. For example, the ability to recognize container markings on both standard and specialized containers ensures comprehensive coverage of all container types in use.

Supplai’s Container Number Recognition Software (CNRS) solutions exemplify the capabilities of modern container number recognition technology. Their systems are designed to deliver fast and efficient container identification, significantly reducing recognition time and improving operational efficiency. By integrating API interfaces, these systems can seamlessly connect with existing logistics platforms, providing real-time data and enhancing overall supply chain management.

The Role of Real-Time Identification in Modern Logistics

Real-time identification in modern logistics is transforming the way the industry operates. By utilizing advanced optical character recognition (OCR) and container number recognition systems, logistics companies can achieve unprecedented efficiency and accuracy. Real-time identification systems, such as Gate OCR and Rail OCR, detect container numbers swiftly and accurately, even under challenging conditions.

One of the primary benefits of real-time identification is the ability to process a high number of containers entering and leaving any port container terminal efficiently. This capability is crucial for managing the flow of goods and reducing congestion during peak hours. Real-time identification systems can recognize container identification numbers and license plates, ensuring that only authorized vehicles and containers are processed.

Moreover, these systems are designed to handle various types of containers, including dry containers and cargo containers. By recognizing specific container markings and identification numbers, these systems facilitate the seamless movement of containers across different transport modes. For example, Supplai their Reach-stacker OCR systems can detect container numbers during loading and unloading operations, significantly speeding up the process and reducing human error.

Supplai, a leader in OCR technology, offers solutions that integrate seamlessly with existing logistics platforms. Their container number recognition system provides accurate recognition of ISO 6346 container codes, ensuring compliance with international standards. This integration allows for real-time data processing, which is essential for maintaining an efficient supply chain.

Advancements in Optical Character Recognition (OCR) for Containers

Optical character recognition (OCR) has seen significant advancements in recent years, particularly in the context of container number recognition. These advancements have made it possible to automate the identification and tracking of shipping containers with greater accuracy and speed. Modern OCR systems can process images captured by IP-cameras, detecting container identification numbers even in low-light conditions.

One of the key improvements in OCR technology is its ability to recognize and read various container codes, including ISO 6346. This capability ensures that container identification is consistent and reliable across different ports and terminals globally. Advanced OCR systems can detect container numbers, license plates, and other markings on cargo containers, making them indispensable tools for the logistics industry.

Supplai’s container number recognition system exemplifies the latest advancements in OCR technology. Their system is designed to handle a high volume of containers, providing accurate and real-time identification of container numbers. This system uses advanced algorithms to ensure that the recognition speed is optimized, even under challenging conditions.

Furthermore, OCR technology has expanded to include the recognition of various types of containers. Whether it is a dry container or a refrigerated one, modern OCR systems can accurately identify the container identification number and other relevant information. This versatility is crucial for managing diverse cargo and ensuring that all containers are tracked efficiently.

The integration of OCR with other technologies, such as automatic number plate recognition (ANPR) and object detection, further enhances its capabilities. For instance, combining OCR with ANPR allows for the simultaneous recognition of container numbers and license plates, streamlining the verification process at ports and terminals.

Gate OCR: Enhancing Efficiency at Entry Points

Gate OCR systems such as Supplai their solution are revolutionizing entry point operations in logistics. By leveraging advanced optical character recognition (OCR) technology, these systems facilitate the fast and efficient container identification process. They recognize container numbers, license plates, and other crucial data, streamlining the entry and exit of containers at ports and terminals.

One significant advantage of Gate OCR systems is their ability to handle a high volume of containers entering and leaving any port terminal. This capability is particularly beneficial during peak hours when the number of containers increases dramatically. By automating the identification process, Gate OCR systems reduce the workload on operators, allowing them to focus on more critical tasks.

Gate OCR systems use high-resolution IP-cameras to capture images of containers as they enter and exit. These images are then processed in real-time to detect container identification numbers, container codes, and other relevant information. The systems are designed to work under various lighting conditions, ensuring accurate recognition even at night or in low-light environments.

Supplai, a leader in OCR technology, offers advanced Gate OCR solutions that integrate seamlessly with existing terminal management systems. Their systems provide accurate recognition of ISO 6346 container codes, ensuring compliance with international standards. This integration helps improve efficiency and throughput at busy ports by reducing the time required for manual inspections.

Furthermore, Gate OCR systems enhance security by ensuring that only authorized vehicles and containers gain access. By recognizing license plates and verifying container identification numbers, these systems prevent unauthorized entry and reduce the risk of cargo theft. As a result, they contribute significantly to the overall security of the supply chain.

Rail OCR: Improving Rail Logistics with Advanced Recognition

Rail OCR systems such as the one from Supplai are transforming the logistics landscape by providing advanced recognition capabilities for railway operations. These systems utilize optical character recognition (OCR) technology to identify container numbers, improving the management and monitoring of freight transported by rail. By automating the identification process, Rail OCR systems enhance operational efficiency and accuracy.

One of the key benefits of Rail OCR is its ability to process a large number of containers in real-time. This capability is crucial for maintaining the smooth flow of freight along rail routes. Rail OCR systems detect container numbers, container codes, and other identification markers as trains pass through scanning points, ensuring accurate data collection and tracking.

Rail OCR systems are designed to work in various environmental conditions, including different lighting and weather scenarios. They use high-speed cameras and advanced OCR algorithms to capture and process images of containers, regardless of their condition. This robust design ensures reliable performance and accurate recognition at all times.

Supplai’s Rail OCR solutions exemplify the cutting-edge technology used in modern rail logistics. Their systems offer fast and efficient container recognition, significantly reducing the recognition time and enhancing the overall efficiency of rail operations. By integrating with existing logistics platforms, these systems provide real-time data that helps operators make informed decisions and optimize freight management.

Moreover, Rail OCR systems contribute to improved security and safety in rail transport. By accurately identifying container numbers and verifying cargo information, these systems help prevent unauthorized shipments and ensure that all transported goods comply with regulatory standards. This verification process is vital for maintaining the integrity of the supply chain.

In addition to enhancing operational efficiency and security, Rail OCR systems also support the automated tracking of containers throughout their journey. This capability allows logistics providers to monitor the movement of containers in real-time, ensuring timely deliveries and reducing the risk of delays.

Crane OCR: Streamlining Container Handling with Optical Technology

Crane OCR systems such as the sytem from supplai are pivotal in modernizing container handling operations at ports and terminals. By utilizing advanced optical technology, these systems automate the identification of containers during loading and unloading processes. Crane OCR systems capture and process images in real-time, ensuring swift and accurate recognition of container numbers.

One of the main advantages of Crane OCR is its ability to handle various types of cranes, such as gantry cranes and ship-to-shore cranes. These systems are designed to read the letters of the container identification codes and the entire container number sequence efficiently. By doing so, Crane OCR systems significantly reduce the time required for manual data entry and inspection, thus improving overall operational efficiency.

We’ve taken great strides in integrating these systems with existing terminal management platforms. For instance, Supplai’s Crane OCR solutions provide seamless integration, allowing for the automatic transfer of data to terminal operating systems. This automated system helps streamline the process and reduces human errors, ensuring that each container is correctly identified and logged.

Crane OCR systems also contribute to enhanced security. By verifying the owner’s prefix and other critical details, these systems ensure that only authorized containers are handled. This verification process is crucial in maintaining the integrity of the supply chain and preventing cargo theft.

Moreover, Crane OCR systems facilitate the accurate tracking of containers, from their entry into the port to their final destination. This capability is essential for meeting the demands of modern shippers who require precise and real-time data about their cargo. The systems also help in inspecting containers for any discrepancies in weight or identification numbers, thus ensuring compliance with regulatory standards.

Reach-Stacker OCR: Fast and Efficient Container Management

Reach-stacker OCR systems are transforming container management in ports and terminals by providing fast and efficient identification solutions. These systems utilize optical technology to read and process container numbers in real-time, enhancing the speed and accuracy of container handling operations.

One significant benefit of Reach-stacker OCR systems is their ability to operate under various conditions, including different lighting and weather scenarios. This robustness ensures that the systems can accurately read the letters of the container identification codes and other relevant details, regardless of environmental factors.

We’ve taken measures to ensure that Reach-stacker OCR systems integrate smoothly with existing logistics and terminal management platforms. Supplai’s Reach-stacker OCR solutions, for instance, offer real-time data processing capabilities that enhance the overall efficiency of container management. By automating the identification process, these systems reduce the need for manual checks, thus saving time and minimizing errors.

In order to improve efficiency, Reach-stacker OCR systems are equipped with advanced algorithms that can handle high volumes of container movements. These systems read and log container details automatically, ensuring that each container’s data, such as the owner’s prefix, BIC code, and maximum weight, is accurately recorded. This automated system not only speeds up operations but also ensures compliance with international standards.

Reach-stacker OCR systems also play a crucial role in the inspection and verification process. By capturing detailed images and data in real-time, these systems allow operators to inspect containers for any discrepancies or issues. This capability is essential for maintaining the integrity of the supply chain and ensuring that all containers meet regulatory requirements.

Moreover, the ability to track and manage containers efficiently helps in optimizing space and resources at the depot. The systems provide precise information about container movements, enabling better planning and utilization of storage areas. This optimization is vital for handling the increasing volumes of container traffic in today’s global trade environment.

License Plate Recognition (LPR) and Automatic Number Plate Recognition (ANPR)

License plate recognition (LPR) and automatic number plate recognition (ANPR) systems are vital tools in modern logistics and container management. These technologies ensure that vehicles transporting containers are accurately tracked and identified. By automating the process of recognizing and recording license plate information, LPR and ANPR systems significantly enhance security and operational efficiency.

One of the main benefits of LPR and ANPR systems is their ability to process data in real-time. This real-time data processing ensures that vehicles are quickly verified and allowed access to ports and depots without unnecessary delays. The systems capture the license plate images, which are then processed to extract the letters and numbers, ensuring accurate recognition.

We’ve taken significant steps to integrate these systems with other container management technologies. For instance, combining LPR with automatic container code recognition allows for the simultaneous verification of both vehicle and container identities. This integration helps prevent unauthorized access and ensures that only verified shipments are handled.

LPR and ANPR systems also support the optimization of freight operations. By providing accurate and timely data, these systems help logistics operators plan and manage the movement of containers more effectively. This capability is crucial in order to improve efficiency and reduce bottlenecks at busy ports and terminals.

Furthermore, LPR and ANPR systems contribute to enhanced security measures. By verifying the license plates and matching them with container numbers, these systems help prevent theft and unauthorized entry. This verification process is essential for maintaining the integrity of the supply chain.

Marking and Detection: Ensuring Accurate Container Identification

Accurate marking and detection of containers are crucial for efficient logistics operations. By ensuring that each container is correctly identified, logistics operators can track and manage the movement of goods more effectively. The use of advanced detection technologies and clear container markings helps streamline this process.

Container markings include a combination of letters and numbers that form the container number. This container number is a sequence that typically follows the ISO 6346 standard, ensuring consistency and reliability across the global supply chain. The owner prefix, which consists of three capital letters, identifies the container’s owner, while the following digits provide unique identification.

We’ve taken steps to ensure that detection technologies are integrated with container management systems. These technologies, such as OCR and RFID, automate the identification process, reducing the need for manual checks. By leveraging these automated systems, operators can quickly and accurately identify containers, even under challenging conditions.

One key aspect of accurate container identification is the ability to read and interpret various markings, including the automatic container code and the letters of the container number. This capability is essential for maintaining the flow of goods through the supply chain and ensuring that all containers are properly tracked.

Furthermore, detection technologies help operators inspect containers for any discrepancies or issues. By capturing detailed images and data, these systems allow for thorough inspections and verifications, ensuring that containers meet all regulatory requirements and standards.

Verification of ISO Container Codes with Advanced Recognition Systems

Verification of ISO container codes is a critical component in maintaining the integrity of the global supply chain. Advanced recognition systems ensure that each container is correctly identified and complies with international standards, such as ISO 6346. These systems use cutting-edge technology to verify the container codes, ensuring accuracy and reliability.

One of the primary benefits of advanced recognition systems is their ability to process large volumes of data quickly. By using simple IP camera’s, real-time video analytics and AI OCR technology, these systems capture and verify the container codes in real-time. This real-time verification helps streamline operations and reduce delays at ports and terminals.

It’s used in various stages of the logistics process, from initial container entry to final delivery. The systems verify the letters and numbers of the container code, ensuring that each container’s identification is accurate. This accuracy is crucial for maintaining the flow of goods and preventing errors in container handling.

Moreover, advanced recognition systems help verify additional details such as the owner prefix and maximum weight of containers. This comprehensive verification process is essential for ensuring that all containers meet the necessary regulatory standards and are safe for transport.

In order to improve efficiency, these systems are integrated with existing logistics platforms. This integration allows for seamless data transfer and real-time updates, providing operators with the information they need to manage container movements effectively. By automating the verification process, these systems reduce the need for manual checks and minimize the risk of errors.

API Integration: Seamlessly Connecting OCR Systems with Existing Infrastructure

API integration is a crucial aspect of modern OCR systems, enabling seamless connectivity with existing infrastructure. By leveraging real-time data processing, these integrations ensure that logistics operations run smoothly and efficiently. APIs facilitate the exchange of data between OCR systems and other platforms, providing operators with up-to-date information on container movements.

One of the key benefits of API integration is the ability to handle data in real-time. This real-time capability ensures that any changes or updates are immediately reflected across all connected systems, reducing the risk of errors and delays. For example, when an engine reads a container’s OCR data, the information is instantly shared with the terminal operating system, ensuring accurate tracking and management.

Companies like Maersk benefit significantly from API integrations. By connecting their OCR systems with their existing logistics platforms, they can streamline operations and enhance efficiency. The ability to process large volumes of data quickly and accurately is vital for handling international shipping demands and maintaining a competitive edge in the global market.

Furthermore, API integrations support the inclusion of additional data points, such as timestamps and payload information. This comprehensive data collection allows for better decision-making and optimization of logistics processes. Operators can track containers more precisely, ensuring that all movements are documented and verified.

Optical Character Recognition (OCR) in Logistics: A Game Changer

Optical Character Recognition (OCR) technology has revolutionized the logistics industry by automating the identification and tracking of containers. This technology enhances the efficiency and accuracy of logistics operations, making it a crucial tool for companies handling large volumes of goods. By processing container data in real-time, OCR systems ensure that all movements are accurately recorded and managed.

One of the primary advantages of OCR in logistics is its ability to handle data internationally. Companies like Maersk rely on OCR technology to track containers across different countries and regions, ensuring that all shipments are monitored and managed effectively. This capability is essential for maintaining the integrity of the global supply chain and ensuring timely deliveries.

OCR systems also enhance the accuracy of data collection. When an engine reads container numbers and other relevant information, the data is processed and verified instantly. This real-time processing reduces the risk of errors and ensures that all information is up-to-date. Additionally, the inclusion of timestamps provides a detailed record of container movements, allowing for better tracking and management.

The integration of OCR with other logistics technologies further enhances its capabilities. For instance, combining OCR with GPS tracking and RFID tags allows for comprehensive monitoring of container movements. This integration supports better decision-making and optimization of logistics processes, ultimately improving efficiency and reducing costs.

Conclusion: The Future of Container Number Recognition

The future of container number recognition is bright, with ongoing advancements in technology promising even greater efficiency and accuracy. As logistics operations become more complex and globalized, the need for robust and reliable container tracking systems will only increase. By leveraging real-time data processing and advanced recognition technologies, companies can enhance their logistics operations and maintain a competitive edge in the market.

One of the key trends in the future of container number recognition is the integration of AI and machine learning algorithms. These technologies can analyze vast amounts of data quickly and accurately, providing valuable insights and predictions. For instance, an engine reads container numbers and other relevant information, processes the data in real-time, and provides operators with actionable insights. This capability supports better decision-making and optimization of logistics processes.

Another significant trend is the increased use of IoT devices and sensors. These technologies provide real-time data on container movements, including timestamps and payload information. By integrating this data with container number recognition systems, companies can achieve a more comprehensive and accurate tracking solution. This integration is particularly beneficial for international logistics operations, where maintaining visibility and control over shipments is crucial.

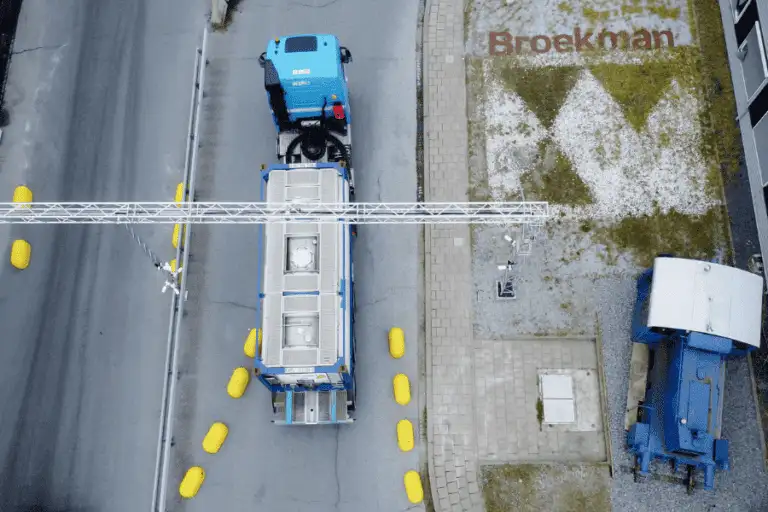

Companies like like Advario, ProRail Broekman and RBC are already leveraging these advanced technologies to enhance their logistics operations. By investing in cutting-edge recognition systems and integrating them with their existing infrastructure, they can ensure the efficient and accurate tracking of containers worldwide.