Introduction to Crane OCR and Its Evolution

Crane OCR (Optical Character Recognition) systems have revolutionized the way terminals handle containers, marking a significant leap in port automation. Initially, the process of identifying and tracking containers in ports was a manual task, heavily reliant on human operators. The introduction of crane OCR systems transformed this process, significantly boosting efficiency and accuracy.

The core function of a crane OCR system is to automatically capture and interpret data from container labels using advanced camera and software technology. This innovation has been particularly pivotal for STS (Ship-to-Shore) crane operations, where rapid and accurate container handling is crucial. By integrating OCR technology into STS cranes, terminals have been able to automate a critical part of their logistics chain.

The evolution of crane OCR systems is closely tied to advancements in camera technology and image processing algorithms. Early OCR systems relied on basic cameras and were limited in their accuracy, struggling particularly with poor lighting conditions or fast-moving containers. Today’s OCR systems, however, use high-resolution cameras that can capture clear images even under challenging conditions. These images are then processed using sophisticated algorithms capable of accurately decoding a wide range of container markings.

The implementation of crane OCR has not only improved the speed of container handling but also enhanced the safety of terminal operations. By reducing the need for manual checks, the risk of accidents and human error is significantly lowered. Additionally, the ability to automate data capture reduces the workload on operators, allowing them to focus on other critical aspects of terminal management.

In summary, the integration of crane OCR systems into port operations has been a game-changer, markedly improving productivity and reliability while ensuring safety in the fast-paced environment of container handling. The continuous advancements in this technology promise even greater efficiency and accuracy in the future, underlining its essential role in modern terminal operations.

The Power of Video Processing in Crane OCR Systems

The integration of video processing in crane OCR (Optical Character Recognition) systems has marked a significant advancement in the field of automation in port and terminal operations. Video processing technology has enabled crane OCR systems to not only capture static images but also analyze moving footage, thereby providing a more comprehensive and accurate understanding of the containers being handled.

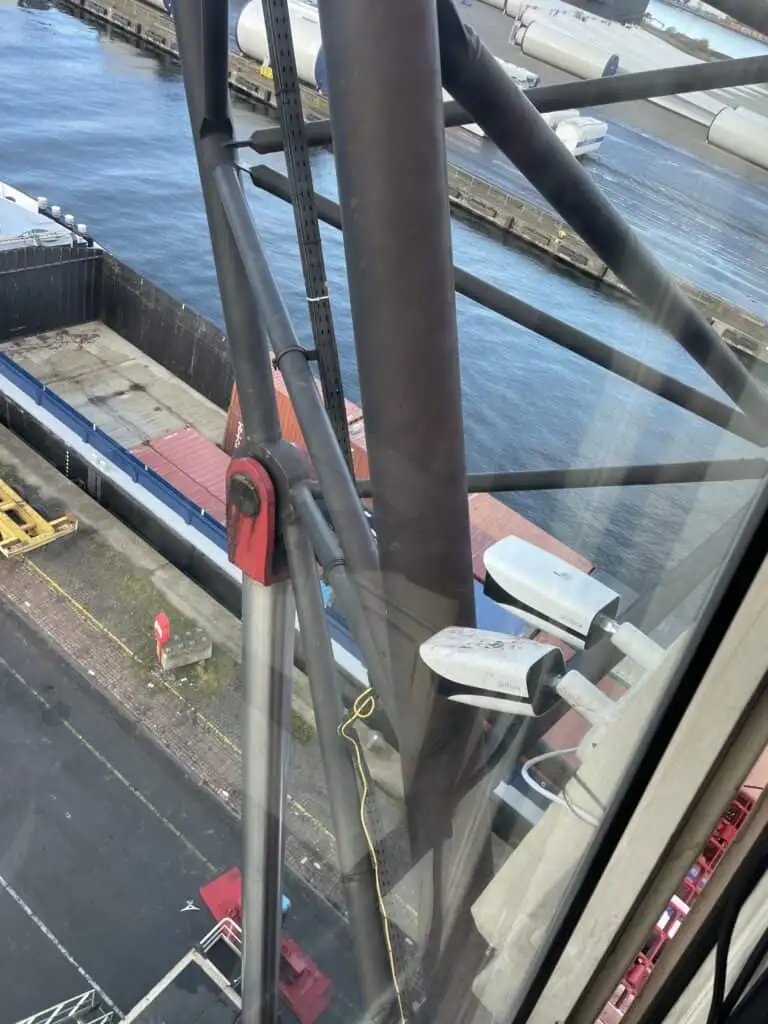

In a typical STS crane, Mobile crane or Gantry Crane operation, a high-definition camera mounted on the crane captures real-time video of the container during the loading and unloading process. This continuous stream of video data provides a dynamic and detailed view of the container, allowing the OCR system to track and record information with exceptional accuracy. This capability is crucial, especially when dealing with fast-moving containers and varying environmental conditions that can challenge the limits of traditional OCR systems.

The real power of video processing lies in its ability to handle a multitude of data points simultaneously. Unlike static image processing, where the focus is on a single frame, video processing analyzes multiple frames per second. This continuous flow of data allows the OCR system to adjust and recalibrate in real-time, significantly enhancing its accuracy and reliability. For instance, if a part of the container code is obscured or unclear in one frame, the system can use data from subsequent frames to complete the picture.

Supplais simple Mobile Harbor Crane OCR – MCH OCR system

Furthermore, the integration of AI (Artificial Intelligence) with video processing has taken crane OCR systems to new heights. AI algorithms can learn and adapt over time, improving their ability to recognize a wide range of container codes and markings under various conditions. This adaptability is essential in a dynamic environment like a port or terminal, where factors such as lighting, weather, and container positioning can vary greatly.

Video processing also enhances the overall safety and efficiency of STS crane operations and even allows Crane OCR for Mobile Crane and Gantry Cranes. With more accurate and reliable data capture, operators can make better-informed decisions, reducing the likelihood of errors and accidents. Additionally, the automation of data capture frees up operators to focus on other critical tasks, further boosting productivity.

In conclusion, the incorporation of video processing into crane OCR systems represents a significant technological advancement, offering terminals unparalleled accuracy, adaptability, and efficiency in their operations. As this technology continues to evolve, it will undoubtedly play a pivotal role in shaping the future of container handling and port logistics.

Crane Operations Transformed: A Closer Look at the Crane and Container Interface

The interface between the crane and container represents a pivotal point in the container handling process within a container terminal. With the advent of crane OCR (Optical Character Recognition) technology, this interaction has been significantly transformed, enhancing both efficiency and accuracy. Crane OCR automatically identifies crucial data from the container, such as ISO codes and container numbers, during the handling process.

A key element in this transformation is the integration of OCR features with terminal tractors and other handling equipment. This integration ensures a seamless hand-off from the crane to the terminal tractor, optimizing the entire loading and unloading process. Moreover, the crane driver is free to operate the crane in the most optimal way, focusing on the balance and positioning of the container without the burden of manual data recording.

Crane OCR solutions have also revolutionized the way containers are stacked in the berth area. With high-quality OCR systems installed, cranes can accurately identify and place containers, significantly improving container inventory accuracy and optimizing the use of space in the stack area. This accuracy is crucial, not only for the efficiency of container terminals but also for maintaining a high level of system reliability.

In terms of safety and operational efficiency, the impact of crane OCR is profound. It reduces the need for physical inspections and manual data entry by clerks, thereby minimizing the risk associated with heavy equipment in the berth area. Furthermore, the system’s ability to capture images and record detailed information about containers, including seal presence and door direction, enhances the overall security and tracking capabilities of the terminal.

In conclusion, the integration of crane OCR technology into crane operations has drastically improved the handling process, from identifying container positions to ensuring accurate data capture in real time. This advancement not only boosts productivity but also elevates the safety standards and operational capabilities of modern container terminals.

Innovative OCR Solutions: Automating Container Handling

The integration of OCR (Optical Character Recognition) solutions in container handling has marked a significant step towards automation in container terminals. Innovative crane OCR solutions, such as those developed by leading crane manufacturers, have automated critical aspects of container handling, including the identification of ISO codes and container numbers, thereby enhancing throughput and container inventory accuracy.

A notable aspect of these solutions is the automatic recognition system, which is installed on various types of cranes, including gantry cranes and ship-to-shore cranes. This system utilizes advanced cameras, often PTZ (Pan-Tilt-Zoom) cameras, and recognition software to accurately identify and track containers throughout the handling process. The captured data is instantly sent to the Terminal Operating System (TOS), ensuring that every transaction, from loading to unloading, is recorded in real time.

Furthermore, crane OCR solutions have made the crane driver free to operate the crane in the most optimal way. This freedom is crucial for ensuring the safety and efficiency of crane handling. The driver can focus on the physical maneuvering of the container, while the OCR system takes care of the data capture, significantly reducing manual errors and improving overall system reliability.

Exception handling is another critical feature of these OCR solutions. In cases where the OCR system encounters anomalies or uncertainties, such as unclear container labels or obscured views, the system can either resolve these exceptions automatically or flag them for manual intervention. This ensures a highly reliable and seamless container handling process, essential for maintaining the continuous flow of operations in busy container terminals.

In summary, the integration of innovative OCR solutions into container handling has automated and streamlined the process, significantly improving accuracy, velocity, and reliability. These advancements have not only enhanced productivity but also contributed to a safer and more efficient container terminal environment.

Diverse Applications of Crane OCR Across Different Crane Types

The integration of Crane Optical Character Recognition (OCR) technology has significantly enhanced the efficiency and accuracy of various types of cranes used in modern logistics and port operations. Each crane type, equipped with OCR systems, plays a unique role in the seamless handling of cargo, demonstrating the versatility and adaptability of OCR technology.

Gantry Cranes

Gantry cranes, often the backbone of major port operations, have seen remarkable improvements with the adoption of crane OCR. Equipped with high-resolution cameras and advanced OCR software, these cranes efficiently manage the loading and unloading of containers from ships, dramatically reducing manual data entry and enhancing operational speed.

Rubber-Tyred Gantry (RTG) Cranes

RTG cranes, vital for yard management, have embraced OCR technology to automate container tracking as they move and stack containers. OCR systems on RTG cranes help in maintaining an accurate inventory of the containers in the yard, thereby optimizing space utilization and operational workflow.

Mobile Harbor Cranes

For smaller ports and versatile operations, Mobile Harbor cranes (MHC) equipped with OCR systems offer flexibility and efficiency. These cranes, often used for both container and general cargo, leverage OCR technology for quick identification and handling of various cargo types, adapting to the diverse needs of smaller or multi-purpose terminals.

Railway Gantry Cranes

In railway applications, gantry cranes with OCR bring efficiency to the construction and maintenance of intermodal railway terminals. The OCR systems enable quick identification and placement of heavy rail components, streamlining the logistics involved in railway construction and upkeep.

In conclusion, the integration of Crane OCR technology across various types of cranes has revolutionized the logistics and port operations industry. From the towering gantry cranes to the agile straddle carriers, OCR systems have brought about a paradigm shift in how cargo is handled, tracked, and managed, reinforcing the role of technology in the future of global logistics.

Ship-to-Shore (STS) Cranes

In the realm of ship-to-shore operations, STS cranes with OCR systems represent a leap in technological advancement. The OCR aids in identifying container information quickly as it is being moved, streamlining the entire process from ship to dock and ensuring accurate tracking and placement in the terminal.

Rail-Mounted Gantry (RMG) Cranes

RMG cranes, similar to RTGs but operating on rails, benefit significantly from OCR systems. The integration of OCR technology enhances their ability to handle high-volume container movements with precision, ensuring accurate stacking and retrieval in the terminal’s storage areas.

Straddle Carriers and Reach Stackers

Straddle carriers and reach stackers, though smaller than gantry cranes, significantly benefit from OCR technology. OCR systems in these cranes assist in the swift movement and stacking of containers, enhancing the fluidity of operations within the terminal.

Enhancing Security and Safety with Advanced Crane OCR Systems

The incorporation of advanced crane OCR systems significantly enhances security and safety in container handling operations, particularly in the complex environments of container terminals. A crane OCR solution typically includes a range of OCR features, pivotal in identifying and verifying container information like seal presence, which is critical for ensuring the integrity of cargo and adherence to international regulations such as the International Maritime Dangerous Goods (IMDG) code.

One key component of these systems is the spreader-mounted camera setup. This configuration allows quay cranes to capture high-quality images of the containers’ top and sides, facilitating comprehensive data collection for each container being handled. This data includes crucial details like container numbers, ISO codes, and even the detection of any potential damage, significantly reducing the need for physical inspections.

The application of optical character recognition technology within these systems is instrumental in maintaining accuracy and velocity in data processing. With the integration of advanced software, including PLC (Programmable Logic Controller) systems, crane OCR solutions can accurately interpret container data, minimizing human error, and enhancing system reliability. The use of tandem spreaders in these systems further boosts efficiency, allowing simultaneous handling of multiple containers and speeding up the loading and unloading process.

Moreover, the integration of these OCR systems with centralized control systems and portal interfaces ensures that all captured data is instantly and securely transmitted to the terminal’s operational database. This seamless data flow allows terminal clerks and other personnel to access up-to-date container and cargo information in real-time, facilitating efficient and informed decision-making.

In summary, advanced crane OCR systems play a crucial role in enhancing the safety and security of container terminals. By providing detailed and accurate container information, they ensure compliance with international regulations, minimize the risk of accidents, and streamline the handling process, contributing to the overall efficiency of container terminal operations.

Exploring the Advanced OCR Features of Supplai’s System

Supplai’s crane OCR system stands out with its array of advanced OCR features, designed to optimize container handling processes in ports and terminals. One of the key aspects of this system is its sophisticated optical character recognition technology, which is adept at accurately identifying container details like ISO codes, cargo details, and seal presence.

An integral feature of Supplai’s system is the spreader-mounted cameras, which are crucial for capturing high-quality images of containers from various angles. These cameras, often installed on gantry cranes and quay cranes, are essential for ensuring comprehensive data capture. Additionally, the system’s configuration is designed to accommodate various types of crane operations, including tandem lifts, thus enhancing the versatility and applicability of the solution across different terminal setups.

The inclusion of license plate recognition technology further adds to the system’s capabilities, enabling it to link containers with terminal tractors and other transport units within the terminal. This integration ensures a more streamlined and automated hand-off process, improving the accuracy and efficiency of container tracking.

Furthermore, Supplai’s system boasts high system reliability, thanks to its built-in mechanisms for exception handling and damage archiving. In instances where the OCR system encounters unclear or obstructed container labels, the system can efficiently handle these exceptions, either by resolving them automatically or flagging them for manual intervention. This ensures continuous and uninterrupted operation, crucial for maintaining the throughput of the terminal.

In terms of safety and compliance, the system’s ability to detect and report seal presence and adhere to IMDG regulations is of paramount importance. This feature ensures that containers carrying hazardous materials are handled appropriately, maintaining safety standards within the terminal.

In conclusion, Supplai’s advanced OCR features mark a significant advancement in crane OCR technology, offering unparalleled accuracy, versatility, and reliability in container handling operations. These features collectively contribute to optimizing terminal operations, enhancing safety, and ensuring compliance with international shipping and handling standards.

Integration and Compatibility: Crane OCR System in the Modern Port Ecosystem

The integration of crane OCR systems into the modern port ecosystem marks a significant stride in operational efficiency and accuracy. Centralized control is at the heart of this integration, allowing for seamless communication between the crane OCR system and other elements of the port’s operational network. This integration ensures that checker information, such as container IDs and cargo details, is instantly and accurately relayed to the port’s central management system.

An essential aspect of this integration is the built-in compatibility of crane OCR systems with existing terminal operating systems. This compatibility is crucial for ensuring that units, which were manufactured for years with different specifications, can seamlessly integrate into the modernized setup without necessitating extensive overhauls. Moreover, the long-lasting durability of these systems, often said to last forever, ensures that the investment in this technology continues to pay dividends well into the future.

Another key feature of these integrated systems is the optimal way in which cameras installed on cranes capture and relay data. These high-resolution cameras provide clear, detailed images of container labels, regardless of environmental conditions. This capability not only improves the accuracy of data capture but also enhances the overall efficiency of container handling processes.

In conclusion, the integration of crane OCR systems into the modern port ecosystem represents a significant technological advancement. By offering centralized control, built-in compatibility, and optimal data capture capabilities, these systems play a crucial role in modernizing port operations and enhancing overall efficiency and accuracy.

Optical Character Recognition: The Backbone of Modern Crane OCR Systems

Optical character recognition (OCR) technology serves as the backbone of modern crane OCR systems, fundamentally transforming how ports handle container identification and tracking. This technology, known for its precision and reliability, is crucial in decoding the complex information encoded on container labels.

The sophistication of OCR technology lies in its ability to process a vast array of data points from container labels, including ISO codes, company logos, and other identifying marks. This processing is made possible by advanced cameras installed on cranes, which capture high-resolution images of containers as they are loaded or unloaded. These images are then analyzed by OCR software to extract and record the relevant information.

A significant advantage of optical character recognition in crane systems is its ability to streamline the container handling process. For example, the sterilizer is known for its capability to cleanse data, ensuring that only accurate and relevant information is captured and stored. This leads to a substantial reduction in manual data entry, thereby minimizing the chances of human error and enhancing overall system reliability.

Furthermore, the use of OCR technology allows for the long-term archiving of container data, an essential aspect for ports that handle thousands of containers daily. This archived data can be invaluable for future reference, especially in instances where tracking the history of a container becomes necessary.

In summary, optical character recognition is a critical component of modern crane OCR systems, providing unparalleled accuracy and efficiency in container data capture and processing. Its ability to seamlessly integrate with existing port infrastructure and adapt to a variety of container types makes it an indispensable tool in the modern container handling ecosystem.

Exception Handling in Crane OCR: Ensuring Operational Continuity

Exception handling in crane OCR systems is a critical aspect that ensures operational continuity in container terminals. These advanced systems, equipped with sophisticated algorithms, are designed to identify and rectify any discrepancies or anomalies encountered during container recognition processes. This capability is vital for maintaining the seamless flow of operations and minimizing downtime caused by data errors or misinterpretations.

The crane OCR systems are programmed to flag any instances where the captured data does not align with expected patterns or is incomplete. These exceptions could arise from various factors such as poor visibility, damaged container labels, or unusual container positions. When such discrepancies are detected, the system either automatically corrects them based on pre-set rules or alerts the terminal operators for manual intervention. This dual approach ensures that any potential issues are addressed promptly, maintaining the accuracy and reliability of data processing.

Moreover, effective exception handling contributes significantly to enhancing overall system reliability. By swiftly addressing and resolving exceptions, crane OCR systems help avoid bottlenecks in container handling processes, thereby enhancing the terminal’s productivity. Furthermore, this proactive approach to managing exceptions reduces the reliance on manual data entry, decreasing the likelihood of human error and enhancing operational efficiency.

In conclusion, the role of exception handling in crane OCR systems is indispensable for ensuring uninterrupted operations in container terminals. By effectively identifying and addressing data discrepancies, these systems play a crucial role in maintaining the continuous flow of operations, thereby underpinning the terminal’s productivity and operational efficiency.

Seamless Hand-Off: Enhancing Crane Operational Efficiency

The concept of seamless hand-off in crane operations is pivotal in enhancing operational efficiency in container terminals. This process involves the smooth transfer of containers from the crane to other handling equipment, such as terminal tractors or conveyor systems, facilitated by advanced crane OCR (Optical Character Recognition) systems. The efficiency of this hand-off process directly impacts the overall speed and effectiveness of container handling in the terminal.

Crane OCR systems play a crucial role in ensuring a seamless hand-off. By accurately identifying and tracking containers, these systems provide real-time data to terminal operators, enabling them to coordinate the movement of containers efficiently. This coordination is essential for minimizing the time containers spend suspended in air or waiting for further handling, thereby reducing cycle times and increasing the throughput of the terminal.

Furthermore, the integration of crane OCR systems with other terminal operating systems enhances the hand-off process. By providing accurate and up-to-date information on container location and status, crane OCR systems enable terminal operators to plan and execute container movements more effectively. This integration helps in optimizing the utilization of handling equipment and reducing unnecessary movements, further improving the terminal’s operational efficiency.

In summary, the seamless hand-off of containers facilitated by crane OCR systems is a key factor in enhancing operational efficiency in container terminals. By ensuring accurate and timely transfer of containers between different handling equipment, these systems help streamline operations, reduce handling times, and increase the overall throughput of the terminal.

Conclusion: The Future of Crane OCR and Its Impact on Port Logistics

The future of crane OCR (Optical Character Recognition) technology in port logistics appears not only promising but also transformative. This technology, already pivotal in modernizing container handling processes, is poised to evolve further, driving significant improvements in operational efficiency, safety, and data management in ports worldwide.

Looking ahead, the continuous advancements in AI and machine learning promise even more sophisticated crane OCR systems. These future systems are expected to feature enhanced accuracy in data capture, greater adaptability to varying environmental conditions, and improved integration with other technological systems within the port ecosystem. Such advancements will further streamline container handling processes, reducing turnaround times and increasing throughput.

Another area of potential growth lies in the integration of crane OCR technology with emerging digital trends like the Internet of Things (IoT) and blockchain. This integration could lead to more comprehensive data tracking and management solutions, offering real-time visibility of cargo across the entire supply chain. This level of transparency and efficiency could revolutionize the way ports operate and interact with other segments of the logistics chain.

In terms of sustainability, future developments in crane OCR technology could also contribute to more environmentally friendly port operations. By optimizing container handling processes, ports can reduce fuel consumption and emissions, aligning with the global push towards greener logistics practices.

In conclusion, crane OCR technology is set to play an increasingly critical role in shaping the future of port logistics. Its impact will likely extend beyond operational efficiencies to include broader aspects such as supply chain transparency, sustainability, and the integration of ports into the global digital infrastructure. As this technology continues to evolve, it will undoubtedly remain a key driver in the ongoing modernization of port operations.

FAQ: Understanding Crane OCR in Container Handling

In the evolving landscape of port logistics, Crane Optical Character Recognition (OCR) has emerged as a crucial technology, significantly enhancing efficiency and safety. This FAQ section aims to address common queries and provide insights into how Crane OCR technology operates, its benefits, and its impact on modern port operations. Here, we delve into the most frequently asked questions to offer a clearer understanding of this transformative technology.

What Is Crane OCR and How Does It Work?

Crane Optical Character Recognition (OCR) is a sophisticated technology used in ports to automate the identification and tracking of containers. It employs high-resolution cameras and advanced software to capture and analyze images of container labels, extracting crucial data like container numbers and ISO codes. This system significantly reduces manual data entry, enhancing accuracy and efficiency in container handling processes.

What Are the Key Features of Modern Crane OCR Systems?

Modern Crane OCR systems are characterized by high-resolution image or prefferably video capture, real-time data processing, and integration with terminal operating systems. They typically include features such as advanced AI algorithms for accurate data interpretation, robust exception handling mechanisms, and the ability to operate under various environmental conditions. These features collectively contribute to increased operational efficiency, safety, and data accuracy in container terminals.

How Does Crane OCR Improve Efficiency in Port Operations?

Crane OCR improves efficiency in port operations by automating the data capture process, reducing container handling time, and minimizing errors. For instance, it accelerates the container identification process, with some systems capable of processing data in just a few seconds per container. This automation allows for quicker turnaround times and significantly enhances the overall throughput of the terminal.

Can Crane OCR Systems Integrate With Existing Terminal Operating Systems?

Yes, Crane OCR systems are designed to integrate seamlessly with existing Terminal Operating Systems (TOS). This integration ensures real-time data flow between the OCR system and the TOS, enabling efficient container tracking and management. The compatibility with existing systems allows for streamlined operations without the need for significant infrastructure changes.

What Role Does AI Play in the Functioning of Crane OCR?

Artificial Intelligence (AI) plays a pivotal role in enhancing the accuracy and efficiency of Crane OCR systems. AI algorithms are used to analyze the captured video’s instead of photo’s, accurately identifying and interpreting container information under various conditions. These algorithms are self-learning, continually improving their recognition accuracy based on the data processed, thereby reducing error rates and enhancing system reliability.

How Does Crane OCR Contribute to Safety in Container Handling?

Crane OCR contributes to safety by minimizing human involvement in high-risk areas and reducing the likelihood of errors in container handling. By accurately identifying containers, it prevents misplacements and collisions. For example, advanced OCR systems can reduce manual checks by up to 90%, significantly lowering the risk of accidents and improving overall safety in the hectic environment of port operations.

What Are the Benefits of Using High-Resolution Cameras in Crane OCR?

High-resolution cameras in crane OCR systems offer superior image clarity, enabling the accurate capture of container data even under challenging conditions like low light or high speeds. This accuracy is crucial for reliable data processing, with some systems achieving over 99% accuracy in container identification. These cameras ensure consistent performance, essential for maintaining operational efficiency and reducing the need for manual interventions.

How Does Exception Handling Work in Crane OCR Systems?

Exception handling in crane OCR systems involves identifying and addressing data discrepancies or anomalies during container recognition. When the system detects unclear or incomplete data, it either auto-corrects based on predefined rules or flags the issue for manual review. This process ensures continuous operation and high data accuracy, with some systems reporting error resolution rates exceeding 95%.

What Future Developments Are Expected in Crane OCR Technology?

Future developments in crane OCR technology are expected to focus on enhanced AI capabilities, better integration with IoT devices, and greater adaptability to diverse port environments. These advancements aim to further improve recognition accuracy, automate more aspects of port operations, and provide more comprehensive data for supply chain management, potentially increasing operational efficiency by up to 30%.

What Impact Has Crane OCR Had on Global Port Logistics?

Crane OCR has significantly impacted global port logistics by streamlining operations, improving turnaround times, and enhancing data accuracy. It has enabled ports to handle larger volumes of cargo more efficiently, with some reporting up to 20% improvements in operational throughput. This technology has become crucial for ports aiming to stay competitive in the rapidly advancing logistics and shipping industry.