Haringvliet, Numansdorp, Nederland. 25 July 2022

Startup supplai has been engaged by Volker Engineering Structures (VES; part of Volker Wessel) to develop a method together with DDC Smart Inspections (Dutch Drone Company) for a smarter inspection at the Haringvliet bridge. DDC carried out a drone inspection and developed an advanced 3D model. Based on this data, supplai applied its real-time video analytics based on artificial intelligence (AI). In this way , a drone can now be used to perform rapid and accurate inspections.

Work

The driving deck of the lifting part of Haringvlietbrug consists of aluminum plates that are attached to the flap of the bridge with spring clamps. Due to the traffic that drives over the bridge, these spring clamps shiver loose. The lifting part and the movement mechanism will be completely replaced, but this will take some time. Until then, the maximum speed on the A29 of the Haringvliet Bridge is only 50 km/h.

In order to determine the safety of the Haringvliet bridge, it is very important to inspect the construction properly and weekly. This time-critical inspection requires high accuracy and must be done safely. At the moment, VES employees have to pass under the bridge in a maintenance cart to inspect each plate. During this inspection it is prohibited to pass under the lifting part.

Edge Computing

Supplai is an expert in real-time video analytics through artificial intelligence (AI) on edge computing. Supplai recently received a subsidy for this from the MIT R&D AI fund that was paid out for the first time. This Edge computing is mounted directly on the drone during flight and enables real-time video analytics. Due to the use of drones and real-time video analytics, no people are needed to do manual recordings under the bridge.

Because the photos of each flight can be viewed afterwards, a better data-driven way of inspection is created. The degradation is easier to map and there is always reference work. This makes maintenance inspection safer and more accurate. The use of drones ensures that shipping no longer needs to be blocked. The drone only needs to make flights to fully map the underside of the bridge. Unlike slow artificial intelligence (AI) post-processing techniques of drone data, supplai’s edge-computing real-time video analytics can be performed with the help of supplai. These drones collect a large amount of data. The AI deep learning algorithms ensure that the right data is efficiently extracted from the images immediately during the flight.

The advantage of these new techniques is that the inspection frequency can be increased, and immediate action can be taken if a defect is detected. The data-driven way of inspection reduces the chance of errors. The advantage of these new techniques is that the inspection frequency can be increased, and immediate action can be taken if a defect is detected. The data-driven way of inspection reduces the chance of errors. The advantage of these new techniques is that the inspection frequency can be increased, and immediate action can be taken if a defect is detected. The data-driven way of inspection reduces the chance of errors.

3D-Modelling

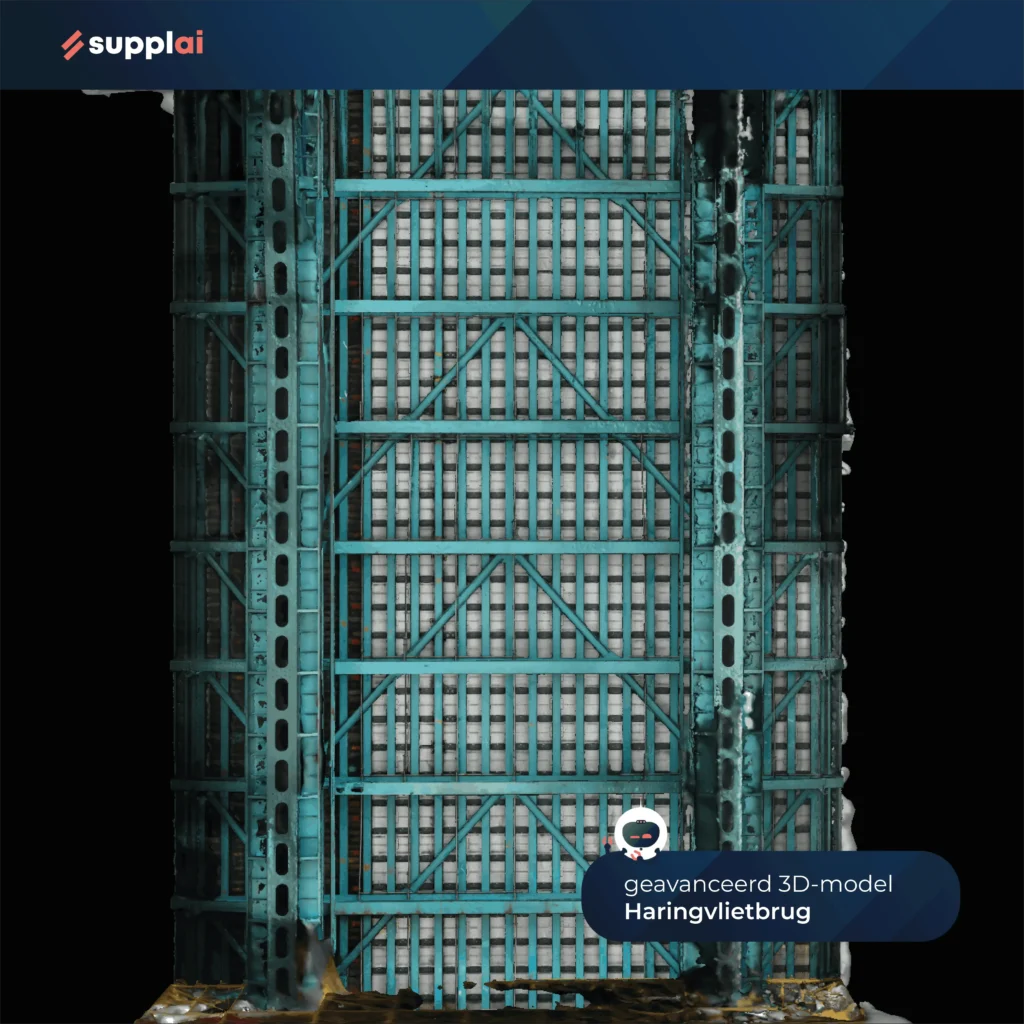

After the inspection, DDC makes a state of the art 3D model. 3D modeling (3D modeling) is the process of creating a mathematical representation of a three-dimensional object. 3D modeling makes it possible to represent objects such as buildings and infrastructure in 3D. This ensures that an inspector can view an object in detail from different angles

The result: a highly detailed and extensive artificial intelligence (AI) presorted dataset of detected spring clamps, which was then processed into an advanced 3D model of the Haringvliet bridge. Fast and data-driven maintenance with less deployment of (scarce) employees and increased safety around the sailing area of the Haringvlietbrug.

The Companies

supplai

Our focus is on developing advanced artificial intelligence (AI) algorithms for businesses in the physical domain. We are therefore a partner that can help you with various current and future transactions with a focus on the long-term relationship. Our practical and applicable artificial intelligence (AI) based algorithms improve business processes by

– reading (document automation)

– see (real-time video analysis)

– analyze and predict (data predictions)

giving you more valuable data and statistical insights into your business processes, improving quality and freeing up valuable time for more strategic tasks.

In this way we help companies and employees to thrive in more complex tasks! Thanks to our extensive knowledge of logistics, (manufacturing) industry, infrastructure and agriculture, we understand what is important for companies and business operations. This makes us the ideal sparring partner to improve your processes using this new technology. At our office we produce 8000 kW of solar energy every year. We heat electrically and train our AI algorithms with our 100% solar power. As a company, we have zero emissions by developing sustainable solutions. With a growing number of customers and partners, we offer ideal solutions to help your business grow!

For more information on state-of-the-art, state-of-the-art artificial intelligence (AI)-based solutions, visit supplai.nl

DDC Smart Solutions (Dutch Drone Company)

The Dutch Drone Company was founded with the aim of providing industry solutions for faster and safer inspections and data services. One of these solutions is the use of drones (UAVs). DDC has a team of experts in the field of data analytics with which the collected data can be processed and analyzed in an advanced way.

For more information, visit: www.ddc.works

Volker Engineering Structures (VES)

Volker Engineering Structures is expert op het gebied van levensduur verlengend onderhoud aan bruggen en sluizen met als missie: een veilig en bereikbaar Nederland voor iedereen. Het VES-team zet zich dag in dag uit in voor het verlengen van de levensduur van multidisciplinaire constructies in de infrastructuur. Hun expertise: bruggen en sluizen onderhouden, renoveren, vernieuwen en verduurzamen. VES is onderdeel van het bouwconcern Volker Wessels. VES is een jong bedrijf met grote ambities en zet zich iedere dag in voor het verlengen van de levensduur van multidisciplinaire constructies in de infrastructuur. VES bestaat sinds 2019 en komt voort uit de afdeling Rail, Weg, Water (RWW) van VolkerRail, een onderneming van VolkerWessels.

Ga voor meer informatie over Volker Engineering Structures naar: www.volkerengineeringstructures.nl